Introduction to Habasit 380J10 Micro-V Belt Grabber PLR

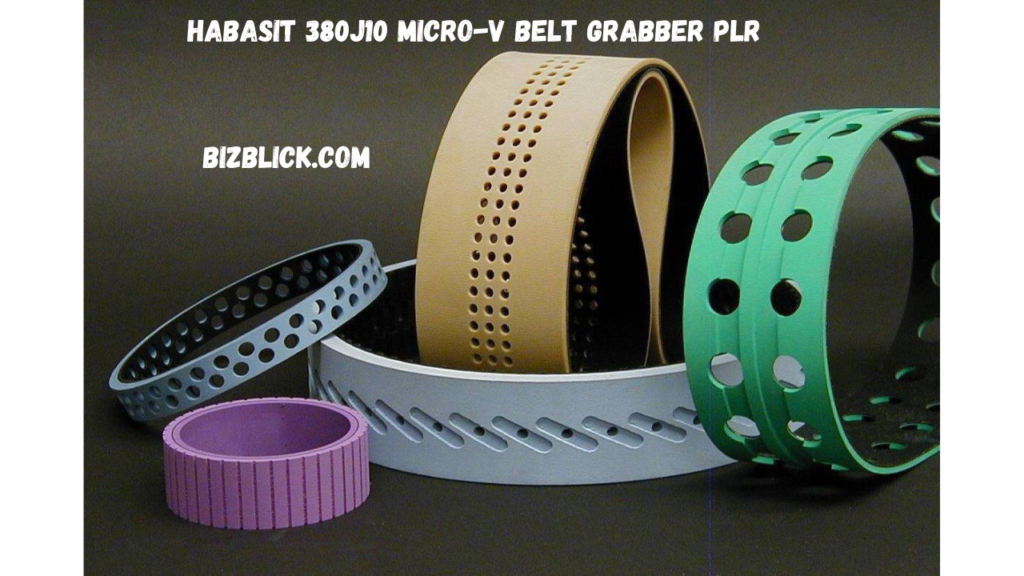

The Habasit 380J10 Micro-V Belt Grabber PLR is an essential component in modern conveyor systems, widely used across industries for its superior performance and high reliability. As part of the renowned Habasit brand’s offerings, this particular Micro-V belt is designed for applications requiring high load handling, durability, and efficient operation. The innovation in belt technology has made Habasit one of the leaders in the field, providing solutions that streamline operations and improve productivity. The Habasit 690J10 Micro-V Belt Grabber PLR also shares similar features, expanding the versatility and application of these high-performance belts.

In this article, we will explore the key features, advantages, applications, and maintenance of the Habasit 380J10 Micro-V Belt Grabber PLR, as well as compare it with the Habasit 690J10 variant to give a clear understanding of how these belts can benefit industries that require robust and reliable conveyor systems.

What is the Habasit 380J10 Micro-V Belt Grabber PLR?

The Habasit 380J10 Micro-V Belt Grabber PLR is part of a specific category of conveyor belts designed for demanding, high-speed applications. Known for its compact design, the Micro-V belt offers improved gripping and a higher coefficient of friction, making it ideal for moving products smoothly without slippage. It is typically used in environments where precise belt control is required, such as in material handling and packaging operations.

The “PLR” in the product name stands for Polyester Low-Resistance, which refers to the belt’s construction that minimizes energy consumption while ensuring that the system runs efficiently. The 380J10 designation signifies its specific design and dimension, which are optimized for particular applications, providing tailored solutions for different types of machinery and conveyor systems.

Key Features and Benefits of the Habasit 380J10 Micro-V Belt Grabber PLR

- Enhanced Grip and Friction

The Habasit 380J10 Micro-V belt is engineered with a unique surface texture that provides a superior grip, especially in applications where the movement of products is crucial. Its high coefficient of friction ensures that items are transported without slipping, which increases the reliability of the conveyor system. - Low Resistance Design

The “PLR” technology embedded in this belt’s construction reduces the overall resistance in the system. This makes it an energy-efficient solution, as less power is required to drive the belt, ultimately reducing operating costs and improving the overall performance of the system. - Durability and Longevity

Habasit belts are known for their durability, and the 380J10 Micro-V Grabber PLR is no exception. The polyester material used in the belt construction ensures that it can handle high loads and operate under harsh conditions. This enhances the lifespan of the belt, leading to fewer replacements and reduced downtime for maintenance. - Customizable Design

One of the standout features of the Habasit 380J10 Micro-V belt is its ability to be customized according to the specific requirements of the application. The belt’s width, length, and surface material can be adjusted to accommodate varying load sizes and environmental conditions, offering a high level of flexibility. - Noise Reduction

The design of the 380J10 Micro-V belt also helps in reducing noise levels. This is particularly important in environments where noise pollution can be an issue, such as food processing plants or packaging facilities. The belt’s construction ensures quieter operation while maintaining its high-performance characteristics.

How Does the Habasit 380J10 Compare to the Habasit 690J10 Micro-V Belt Grabber PLR?

The Habasit 690J10 Micro-V Belt Grabber PLR shares many similarities with the 380J10 version, but it differs in several key areas to suit different industrial needs. Both belts are made with high-quality materials and feature advanced technology, but the 690J10 is typically used for more heavy-duty applications, offering a greater load capacity.

- Load Capacity

The Habasit 690J10 is designed for more intensive applications, handling higher loads than the 380J10. It’s ideal for industries where heavier materials need to be moved, such as mining, heavy manufacturing, or logistics. The 380J10, on the other hand, is optimized for medium-load applications, making it ideal for packaging and light industrial use. - Belt Width and Length

While both belts can be customized, the 690J10 offers more flexibility in terms of width and length to accommodate larger systems. This makes the 690J10 suitable for large-scale operations, where broader conveyor systems are necessary. - Performance Efficiency

Both the 380J10 and 690J10 belts are designed for high efficiency. However, the 690J10 belt is built with enhanced features that allow it to operate under more strenuous conditions, such as in environments with higher temperatures or heavier impacts. The 380J10, though still robust, is better suited for applications where energy efficiency and moderate load handling are the priority.

Applications of the Habasit 380J10 Micro-V Belt Grabber PLR

The Habasit 380J10 Micro-V Belt Grabber PLR can be used in a wide range of industries, owing to its adaptability and advanced features. Here are some common applications:

- Packaging Industry

The packaging industry benefits greatly from the precision and reliability that the 380J10 Micro-V belt offers. It ensures smooth handling of products, whether they are fragile items, small parts, or bulky goods. The belt’s ability to minimize slippage and maximize grip makes it an excellent choice for packaging lines. - Material Handling

In material handling, the Habasit 380J10 provides efficient transportation of various materials across production lines. It is especially useful in industries where continuous, smooth operation is critical, such as in food production or electronics assembly. - Printing and Paper Industries

The precision of the 380J10 Micro-V belt makes it ideal for the printing industry, where high accuracy in material movement is needed. Similarly, the belt can be employed in paper handling systems, where the movement of delicate or large sheets of paper needs to be both controlled and secure. - Textile Manufacturing

Textile mills and factories use the 380J10 belt for its durability and efficient transportation of raw materials or finished products. Its ability to handle delicate materials while maintaining the integrity of the product makes it a valuable tool in textile manufacturing.

Maintenance and Care of the Habasit 380J10 Micro-V Belt Grabber PLR

To ensure the longevity and optimal performance of the Habasit 380J10 Micro-V Belt Grabber PLR, regular maintenance is essential. Here are a few tips for maintaining the belt:

- Regular Inspections

Perform routine checks for signs of wear and tear, especially at the belt’s edges or surface. Early detection of issues like abrasion or damage can prevent costly repairs. - Cleaning and Lubrication

Keeping the belt clean is essential to maintain its grip and performance. Depending on the environment, periodic cleaning with appropriate detergents and lubricants can enhance the belt’s functionality. - Avoid Overloading

While the 380J10 is designed for medium-load applications, overloading can reduce its lifespan. Ensure that the weight limit for the belt is adhered to for optimal performance.

Conclusion

The Habasit 380J10 Micro-V Belt Grabber PLR is an excellent choice for industries requiring efficient and reliable conveyor systems. Its advanced features, such as enhanced grip, low resistance, and durability, make it an invaluable asset for material handling, packaging, and a variety of other applications. When compared with the Habasit 690J10 Micro-V Belt Grabber PLR, the 380J10 offers a more specialized solution for medium-load tasks, while the 690J10 is built for more demanding applications. By understanding the benefits and features of these belts, businesses can make informed decisions on which product best suits their operational needs, ensuring smooth, cost-effective, and reliable conveyor performance.