Introduction to Reverse Mating Press

The reverse mating press is a unique tool widely used in various industries, particularly in manufacturing, to aid in the assembly of intricate components. Unlike traditional mating presses, which are typically employed to push components together, the reverse mating press operates on a different principle that can be highly beneficial for specific industrial purposes. In this article, we will explore what the reverse mating press is, its functions, uses, and the numerous advantages it brings to the table.

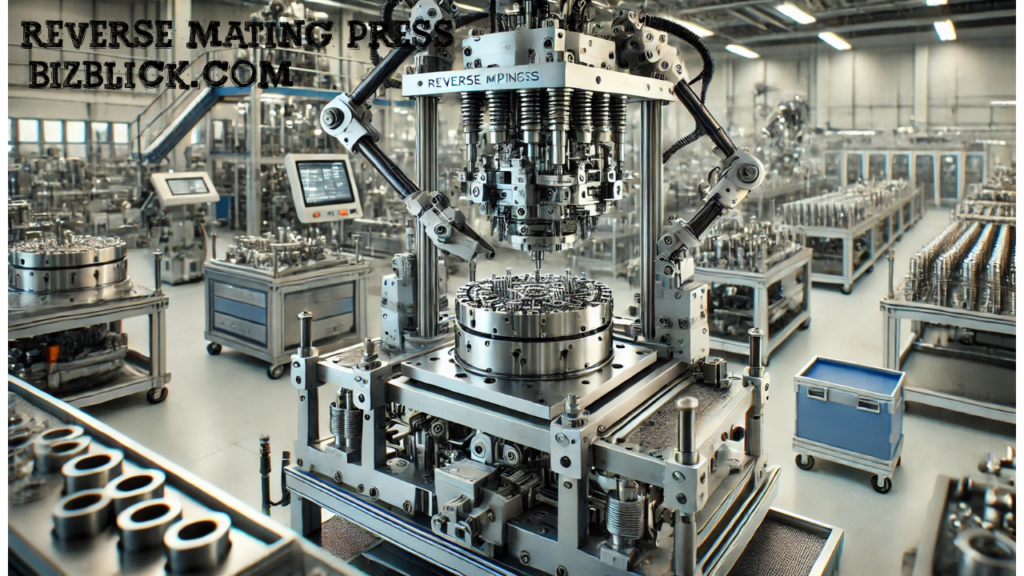

What is a Reverse Mating Press?

A reverse mating press is a type of mechanical press that works by applying pressure in an opposite direction compared to conventional mating presses. Instead of pushing components together, it “pulls” or “holds” them in place, ensuring that parts are precisely aligned during assembly. This press is especially useful when working with parts that need to be securely fastened or when a tight fit is required between multiple components.

The reverse mating press operates with a combination of controlled force, hydraulic or pneumatic mechanisms, and precise positioning, which makes it ideal for delicate tasks requiring a high degree of accuracy. This innovative tool is employed in a range of industries including automotive, aerospace, electronics, and medical device manufacturing, where tight tolerances and alignment are critical.

How Does a Reverse Mating Press Work?

The working mechanism of a reverse mating press can be best understood by looking at the two main components of the press: the mating surface and the press force. In contrast to conventional presses, where force is applied to push components together, the reverse mating press works by generating a pulling or drawing force. This is typically done using hydraulic cylinders or pneumatic actuators, which exert controlled pressure to either pull the parts together or hold them in place until they are securely fastened.

The force applied by the reverse mating press ensures that the components remain in the correct position throughout the assembly process. The press is often equipped with sensors or alignment guides to monitor the precision of the mating operation and to ensure that no misalignment occurs during the press cycle.

Applications of Reverse Mating Press

The reverse mating press has found applications in various industries due to its ability to apply controlled pressure and hold components with extreme precision. Some of the primary applications include:

1. Automotive Industry

In the automotive industry, the reverse mating press is used to assemble complex parts such as engines, transmissions, and other critical components. The precision required in this sector ensures that parts fit together seamlessly, and the reverse mating press helps maintain tight tolerances during the assembly process. Whether it’s joining metal components or ensuring proper alignment of intricate parts, the reverse mating press plays a crucial role in automotive manufacturing.

2. Aerospace Manufacturing

Aerospace manufacturing requires the highest level of precision and reliability. The reverse mating press is instrumental in assembling components for aircraft and spacecraft, where even the slightest misalignment can have significant consequences. The tool ensures that parts such as structural elements, engine components, and avionics are securely assembled and meet the strict safety standards of the aerospace industry.

3. Medical Device Production

The medical device industry relies heavily on precision engineering, and the reverse mating press is often used in the production of devices such as pacemakers, surgical instruments, and diagnostic tools. The ability to hold components together with the required force without damaging delicate parts makes the reverse mating press a valuable asset in medical device assembly.

4. Electronics Manufacturing

Electronics manufacturing also benefits from the reverse mating press, especially when assembling tiny components that must be precisely aligned to ensure functionality. Printed circuit boards (PCBs) and other electronic devices often require a reverse mating press to ensure that the components are securely attached without causing any damage to the sensitive parts.

Benefits of Using a Reverse Mating Press

The reverse mating press offers several advantages that make it a preferred choice in precision assembly processes. Some of the key benefits include:

1. Enhanced Precision and Accuracy

One of the primary benefits of the reverse mating press is its ability to maintain precise alignment during the assembly process. The press is designed to apply controlled force, which ensures that the components are held in place with high accuracy, minimizing the risk of misalignment or defective assembly.

2. Increased Efficiency

By reducing the chances of errors and the need for manual adjustments, the reverse mating press can significantly increase assembly efficiency. The ability to hold parts in place and provide consistent pressure ensures that the entire process runs smoothly, reducing downtime and increasing production output.

3. Prevention of Damage to Delicate Parts

In industries such as medical device manufacturing and electronics, the components being assembled can be extremely delicate. The reverse mating press is gentle on these parts, applying only the necessary force to hold them in place without causing any damage. This makes it ideal for sensitive applications where part integrity is critical.

4. Versatility

The reverse mating press can be adapted to a wide range of assembly tasks, making it highly versatile. It can be used to assemble components of various shapes and sizes, from small electronic parts to large automotive and aerospace components. This adaptability ensures that the reverse mating press is a valuable tool in many different industries.

5. Cost-Effectiveness

Although the reverse mating press may initially appear to be a specialized tool, its ability to reduce errors and improve assembly precision can lead to significant cost savings in the long term. Fewer defects and faster assembly times translate into lower overall production costs.

Challenges and Considerations

While the reverse mating press offers numerous benefits, it also presents certain challenges. For example, the setup and calibration of the press can be time-consuming, especially when working with complex assemblies. Additionally, the tool requires regular maintenance to ensure that the pressure and alignment mechanisms remain in optimal working condition.

Another consideration is the need for skilled operators who are capable of understanding the intricacies of the reverse mating press and using it effectively. Proper training and experience are necessary to maximize the potential of the tool and avoid any potential issues during the assembly process.

Conclusion

In conclusion, the reverse mating press is a versatile and highly effective tool for precise assembly in a variety of industries. By applying controlled force in an opposite direction compared to traditional mating presses, the reverse mating press offers numerous advantages, including enhanced precision, increased efficiency, and reduced risk of damage to delicate components. Whether in automotive, aerospace, medical device, or electronics manufacturing, this tool is a valuable asset for ensuring high-quality assembly with tight tolerances.

As industries continue to demand more precision and efficiency in their manufacturing processes, the reverse mating press will undoubtedly play a key role in meeting these needs. Its ability to hold components securely in place while maintaining alignment makes it a go-to tool for assembly operations that require the utmost attention to detail and accuracy